Lenze relies on the FVA-Workbench for technical sales

With the expertise of a systems provider, Lenze works for and with customers to develop high-quality mechatronic products, powerful hardware and software automation systems, and digitalization services in fields such as big data management, cloud or mobile solutions, and design software for the Internet of Things (IoT). As challenges increase across the mechanical engineering sector, it is essential to be able to rely on capable partners where necessary and focus on core competencies.

A scalable toolbox forms the basis for an efficient value creation chain

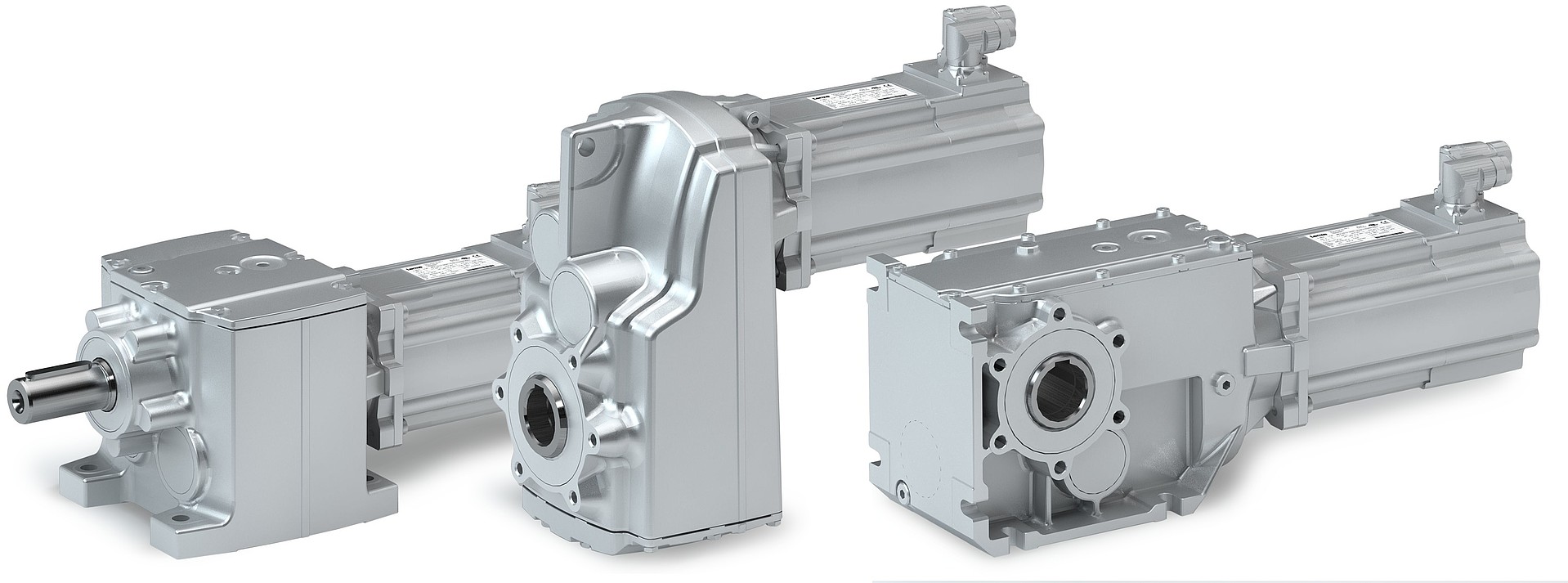

Modular systems are a popular solution for manufacturing industrial gear units, as they allow customers to choose from a wide range of options. Configuration tools enable sales personnel to assist customers with the selection of suitable components. This not only simplifies the sales process, but also leads to more efficient production. Development engineers have clear guidelines on which to base new products, which leads to better planning and faster implementation. The use of common parts can reduce effort and save money, as components can be manufactured in large quantities and reused in different products.

These days, a catalog is much more than just a printed work or a configuration tool. Increasingly, it serves as a company’s treasure chest. Thus, it is essential that everyone involved has appropriate access to data and is able to export it in a suitable format. Product development must be able to add and modify products, and modular designs must be exported so that they can be used as a basis for customizations.

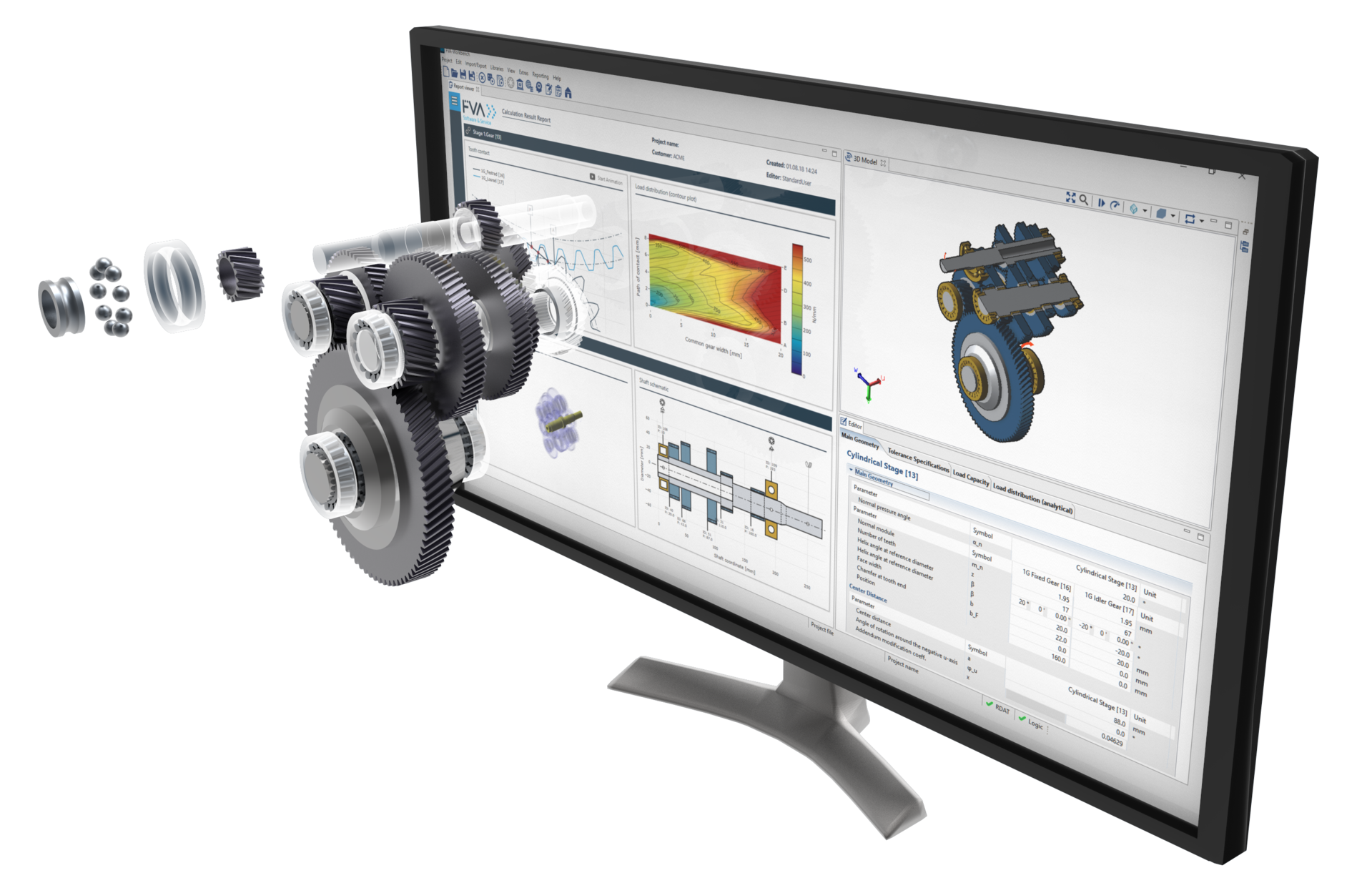

Sales personnel access the product catalog via a configuration tool, working together with the customer to determine optimal solutions. Calculations which consider specific operating loads can be used to help the customer identify variants which best meet their specific needs. The customer is provided with reliable figures which can be used to compare different drive variants with each other. The calculation models are automatically generated from the catalog database.

Shared databases are a central component for efficient work

At Lenze, the catalog is configured as a shared database for development and sales. Technical sales personnel use intelligent features to select suitable motor-gearbox combinations and run calculations based on customer-specific operating data. This provides obvious added value for the customer. Service lives, safeties, and expected loads can all be determined in a short time. Maintenance of the underlying database and the use of simulation tools make it possible to quickly and easily perform technical calculations without having to rely on a central calculation department. In less than a minute, the customer is provided with a data sheet which includes reliable statements about the gearbox based on these technical calculations.

Product development manages the database in the background, adding new products and creating models for automated calculations. A similar gearbox can be loaded from the database as a starting point and modified as needed. This is particularly important, as it ensures that customized products comply with the catalog standard, and that all calculations are uniformly configured. Automatic model generation also leads to enormous time savings for product development.

New products and variants are the result of careful optimizations, especially with regard to the microgeometry design, as this has a significant influence on the characteristics of the final gearbox. Care must be taken to ensure that all relevant loads are considered in order to obtain an efficient, low-noise gearbox with a suitable load capacity. The FVA-Workbench’s powerful reporting system helps users to clearly and easily interpret the results.

The FVA-Workbench is Lenze’s tool for electromechanics

The FVA-Workbench’s extensive automation options can replicate simple tasks or complex processes. Data can be imported or exported, and calculations can be parameterized and started. The system is designed by engineers for engineers so that automation can be easily implemented without additional skills. The FVA-Workbench fits perfectly into Lenze’s configuration and design tool environment.

An intuitive user interface is also available for new product design. It can be used to design, modify, parameterize, and calculate new gearboxes. The parametric construction of the model makes it easy to make modifications.

In addition to a large number of standard load capacity calculations for a wide range of drive components, simulations are also available for noise behavior, loss behavior, and local loads. Even complex geometries such as casings can be considered in the calculation.

With its roots in Forschungsvereinigung Antriebstechnik e.V. (FVA), users of the software can be assured that all calculations have been compared with bench tests and verified by the best universities in Germany.

Lenze has been involved in FVA’s research activities for over 50 years, and is active in the board of directors. Frank Maier, Chief Technology Officer of Lenze Drives GmbH and FVA board member, summarized this commitment as follows: “Lenze’s customers value reliability. Using the FVA-Workbench for technical sales makes it possible to save time and money with automation in product development, while also ensuring calculation quality.“

More automated calculations

Modular systems are revised at regular intervals, whether this is due to market or customer requirements, or new research results that are available in the FVA-Workbench. An entire series, and potentially all installation positions, are often calculated during such a revision. This quickly results in a large number of variants, all of which must be calculated correctly.

In this case, all relevant models can be exported from the Lenze product database for mass calculation. This level of automation makes catalog revisions quick and easy, including evaluation of the calculations. Manual maintenance of tables is no longer required.

These days, Lenze rarely relies on manual gearbox optimizations. In many cases, expertly designed automated processes are used for variations. Defining modifications to the model in advance saves manual configuration time. Calculations can be processed and evaluated quickly. As a consequence, the number of calculations is constantly increasing. Companies are often faced with the challenge of how to reduce calculation times. The FVA-Workbench offers a wide range of time-saving mechanisms which are continuously adapted to industry requirements.

Conclusion

With the FVA-Workbench, Lenze has a powerful tool for quickly and easily performing all gearbox development tasks. The high level of automation is crucial for productivity and makes it possible to use calculations in sales discussions. Catalog databases are maintained which are directly linked to these calculations.