Using Tribologically Optimized Internal Gear Designs to Increase the Load Capacity of Planetary Gearboxes

FVA Research Project 482 V

Introduction

In contrast to external gears, internal gears can relatively easily place the rolling point C outside the meshing path of the gear. Depending on the design, negative specific sliding can be completely avoided on either the planet or the ring gear and the amount of specific sliding can be reduced. The micropitting, pitting, and wear resistance of internal gears can be influenced by shifting the rolling point.

Extensive theoretical and experimental investigations on the influence of the position of the rolling point and the sliding conditions on the tooth flank of internal gears were performed as part of FVA Research Project 482. The results confirm that the sliding conditions have a clear influence and show that positive specific sliding can significantly increase the load carrying capacity of the partner. Based on these results, load capacity parameters and limit load capacities were derived for various common material pairings and classified as state-of-the-art. The existing calculation methods for micropitting, pitting, and wear resistance were also reviewed and expanded.

This online seminar will present selected results of FVA Research Project 482 V.

Target Audience

Everyone who is interested in learning about the results of FVA Research Project 482 V

Main Topics

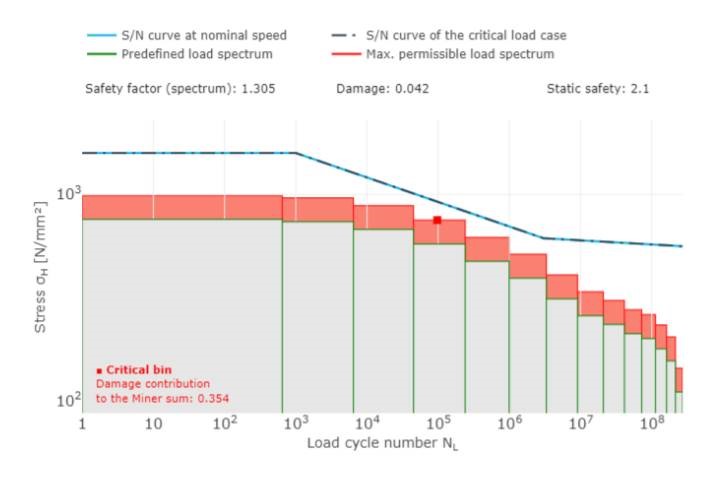

- Service life of cylindrical gears according to ISO 6336-6

- Accumulated roller bearing life

- Service life of notches according to FKM

- Load spectra for multiple gears

- Service life of bevel gears

Objectives

The objective of the web seminar is to present the functionalities of the FVA-Workbench in gear design and to teach them using suitable examples.

Instructors

Michael Geitner

TU München, Forschungsstelle für Zahnräder und Getriebebau (FZG)