REXS at ZF

Gearbox development based on the latest research

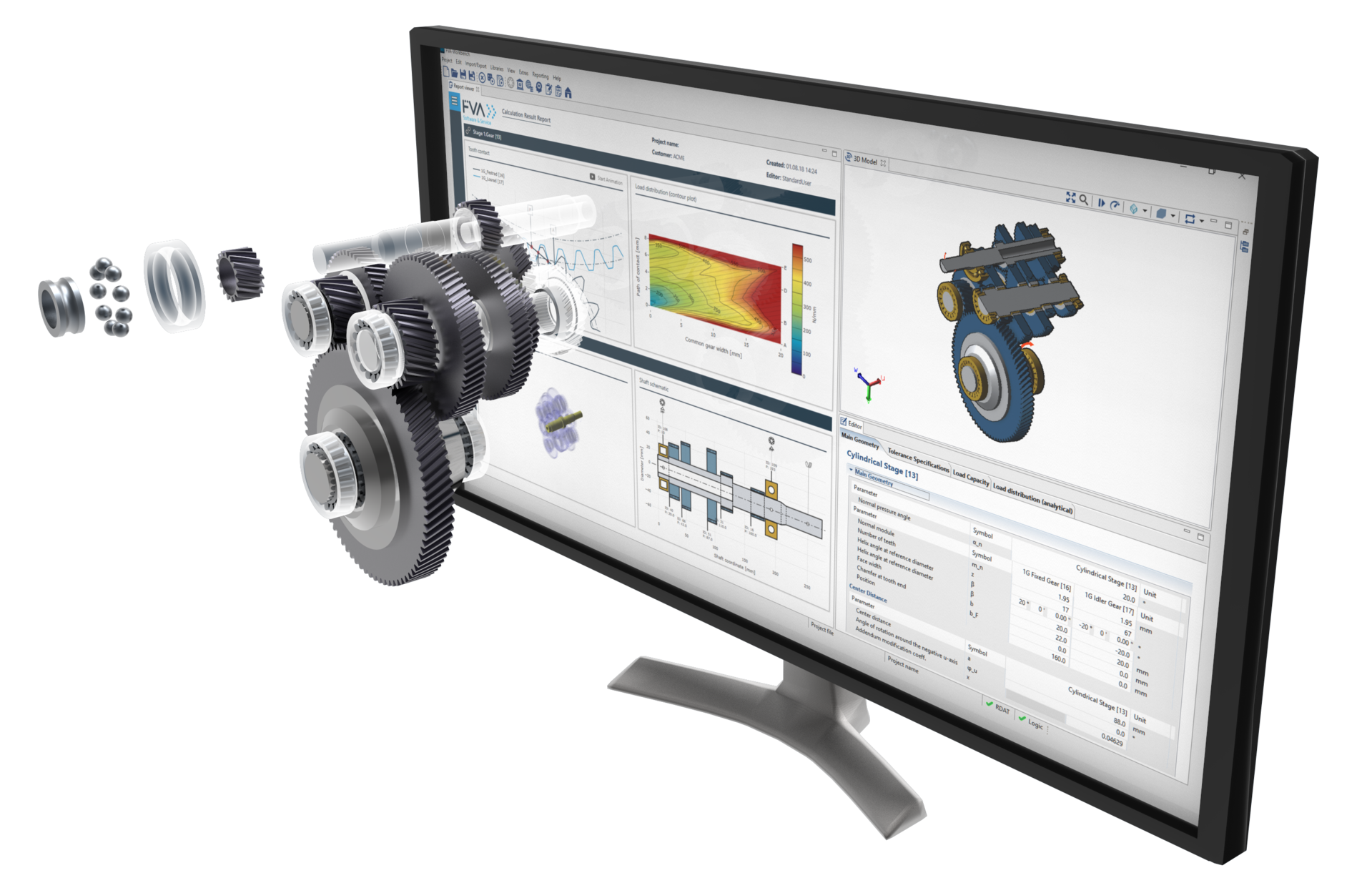

The FVA-Workbench is the leading software tool for calculation and simulation of individual gear elements and complex gear systems. It bundles the knowledge from over 50 years of research from the world’s leading drive technology research and innovation network: Forschungsvereinigung Antriebstechnik e.V. (FVA). New research findings are continuously defined, developed, and validated in cooperative industrial research projects and systematically integrated into the FVA-Workbench. Thus, the software always reflects the current state of research along with classic calculation methods according to standards.

The FVA-Workbench can be used to design and configure complex gear systems and features modules for performing extensive calculations. This approach assists users with calculation selection and parameterization.

REXS – the standardized interface for the simple exchange of gear unit data

A key milestone for Industry 4.0 is establishing industry-wide standards. Combining software systems with end-to-end processes simplifies day-to-day work and reduces the likelihood of errors. Very specific questions often arise, such as the coordinate systems, definition ranges, or interfaces. But even if all of these questions can be clarified in advance, the development of such interfaces can be a complex task that requires both engineering and IT expertise.

FVA e.V. has committed itself to the goal of establishing an industry-wide standard for the simple exchange of data in gearbox development. Since 2017, FVA has been working closely with industry and research to develop the Reusable Engineering EXchange Standard (REXS) - an open source data interface with tailored solutions for drive technology applications. REXS defines a unified modeling and nomenclature for the gearbox and its components across standards and industries, based on the detailed terminology of 25 FVA project committees.

As reference software for the development of the interface, the FVA-Workbench can always import and export gear models in the current REXS format. This makes it possible to transfer models between different CAE systems in order to take advantage of their respective strengths. The aim of the REXS initiative is to provide a "digital twin" in gearbox development and calculation. With many years of experience and close ties to industry and research, FVA is in a unique position to develop a standard that can be adopted industry-wide.

REXS 1.5 published

Adaptations to the specification resulting from user requirements are published annually in a new release. Requirements and change requests are collected in a public ticket system and presented to the Change Control Board (CCB), which oversees and guides the REXS development process. This ensures target-oriented development of the standard.

The latest release, REXS 1.5, makes it possible to reference external data sources. For example, components and their subcomponents and relations can now be used in a REXS file without duplicating them. This allows for a more modular structure to REXS files.

Transferring data from calculation programs often leads to redundancy and overdetermination. This leads to the question of which data was provided by the user and which was calculated. The new “origin” tag can be used to define whether a value was calculated or user-specified. This makes it easier to decide which values should be taken from the model when importing the data.

Furthermore, it was also determined how REXS models can be represented in JSON file format.

REXS design principles

- Free and open

Detailed, non-propriety documentation that is available to everyone free of charge. - Comprehensive and clear

Modeling of the complete gearbox, including all available data (inputs and results). All components of the model are modeled as explicitly as possible ("gearbox snapshot"). - Well documented

All concepts, conventions, and parameters used must be well documented in order to avoid ambiguity or misunderstandings. - Standardized

Use of specific, unambiguous definitions as well as general rules and conventions. Avoidance of special cases and exceptions. Based on common file formats (XML, JSON, ZIP). - Simple and generic

The structure of the interface format as well as the underlying gearbox model should be as simple and generic as possible, depend on few meta-elements, and allow extensions of the model without introducing new structures. - Bilaterally extensible

It should be possible to extend REXS with mutually-agreed data in order to consider special requirements for exchanging data between two software environments.

REXS – the standard for gearbox development’s digital twin

The REXS standard interface has been developed since 2017 on behalf of FVA (Forschungsvereinigung Antriebstechnik e.V.) under an open source license. Research institutes such as TU Dresden IMM, RWTH Aachen WZL, and TU Munich FZG, as well as leading drive technology companies such as SEW-Eurodrive, Schaeffler AG, and ZF are involved in the development. REXS has been developed with the common goal of exchanging and enriching data along the value chain in order to create a complete digital twin of a drive. The FVA-Workbench simulation software supports importing and exporting of all versions.

“Thus, the FVA-Workbench will be a data donor for the digital twin in gearbox development,” explained Norbert Haefke, Managing Director of FVA GmbH.

REXS in use at ZF

The commitment of FVA companies and their many years of experience in the field of gearbox software ensure the suitability of the developed concepts to the industrial environment. Numerous OEMs, Tier 1 suppliers, and CAE software providers have already implemented the REXS interface in their tools and software products. In addition to commercial calculation programs, gearbox manufacturers such as ZF Friedrichshafen AG use the standard in their internal software development projects. For example, ZF relies on the free standard for automated calculations in their internal calculation environment.

Based on extensive research and practical know-how, ZF Friedrichshafen AG developed its own load-bearing capacity methods several decades ago, which it has continuously updated to reflect current knowledge. The application of these methods in product development has made a significant contribution to the high quality and performance density of ZF gearbox systems. In the past, these methods were maintained in in-house engineering tools and rolled out to product development. However, as both maintaining and supporting this internal software requires significant cost and effort, commercial tools such as the FVA-Workbench are increasingly being used for product development. Therefore, these internal calculation methods have been integrated into the FVA-Workbench to ensure that all engineers have continued access to these in-house methods.

In order to protect the company’s internal knowledge, the ZF-specific methods were not provided to FVA GmbH during the integration. Thus, ZF made the decision to package the calculations in its own plugin which communicates bilaterally with the FVA-Workbench via a REXS file.

Beyond this specific use case, automated workflows can also be realized across various simulation tools. This makes REXS an important milestone toward independence from manufacturer-specific file formats.

"We rely on a combination of internal and commercial tools in product development at ZF. REXS makes it possible for us to keep models in sync without having to worry about end-to-end changes to the simulation models." – Dr. Johannes König, Head of Fundamentals & Digitalization in Gear Development, ZF Friedrichshafen AG

Conclusion

The requirements of the world’s leading powertrain and suspension technology company, ZF Friedrichshafen AG, played a decisive role in shaping REXS. ZF’s own load capacity methods have been implemented in the FVA-Workbench, which supports REXS as a data interface. Thus, REXS makes it simple to exchange ZF models with customers and process them in the FVA-Workbench.

For a simple introduction to REXS, sample datasets are available at https://www.rexs.info. Exported datasets can also be validated using the free tool. This is an easy way to verify conformity with the specification and ensure that the REXS files can also be used in other programs.