When analyzing complex gear systems, boundary conditions must be modeled as closely as possible.

By coupling FEM structures with the analytical calculation model, it is possible to consider the influence of the gearbox casing, planet carrier, and wheel bodies on the shaft-bearing system and the load distribution across the facewidth in mesh.

Gearbox casing

Planet carrier

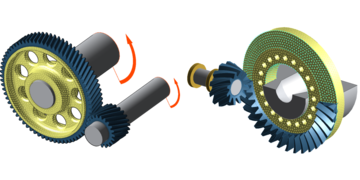

Wheel bodies

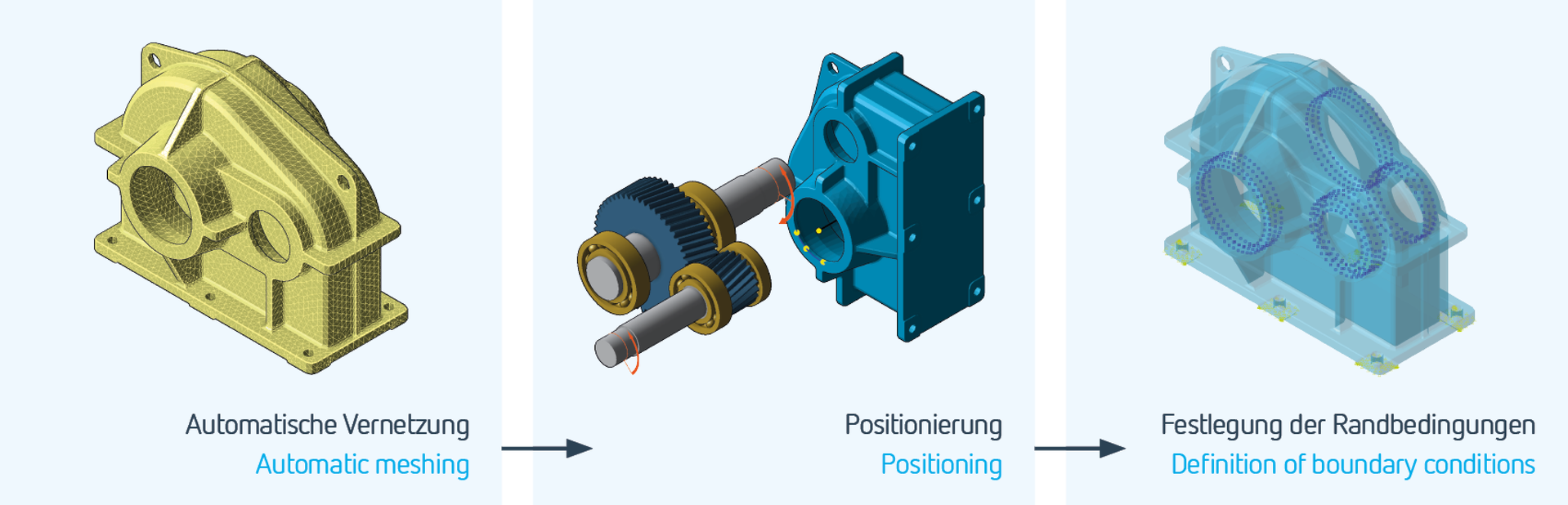

Steps for integrating CAD bodies as FE structures

FE structures are coupled with the analytical calculation model in the FVA-Workbench in 3 steps, with the help of an interactive assistant.

First, the casing must be positioned relative to the gearbox. The FVA-Workbench then automatically detects the coupling nodes of the bearing seats. Finally, the nodes for defining the environment (foundation) can be selected.

Internal meshing of CAD bodies and importing existing meshes

In addition to FE meshes, CAD bodies can also be imported and meshed in the FVA-Workbench. A user-friendly assistant provides support during the meshing process through automation, simple operation, and interactive guidance.

Many small bores in a model can hinder successful FEM meshing. Therefore, the FEM mesher can automatically remove bores from the model. This is particularly useful for small bores, as these do not affect the rigidity of the model.

The meshing size can be adjusted. After successful meshing, the assistant notifies the user whether the quality of the mesh meets the requirements.

To make the workflow particularly efficient, many different native CAD formats can be imported.

Parametric modeling of planet carriers

For planetary gears, the planet carrier in particular has a significant influence on the load distribution. As an alternative to importing externally created FE meshes or CAD bodies, the planet carrier can also be modeled internally. The automatically generated model is meshed and linked to the analytical gear model.

The main features include:

- Internal parameterized modeling of planet carrier geometry

- Single and dual-plate designs are possible

- Internal FEM meshing with just a few clicks

- Integration into the analytical gearbox model

- No need for complex external processing of CAD geometries and FE meshes