The FVA-Workbench serves as a knowledge platform, making the results of FVA research projects available and accessible to all engineers. It is no longer necessary to read through and study countless pages of scientific documentation, making the development of innovative gearboxes considerably more efficient and user friendly. The following article will explain the detailed calculation of rolling bearings in the FVA-Workbench, based on consideration of the profiling of roller bearings.

Profiling of Roller Bearings

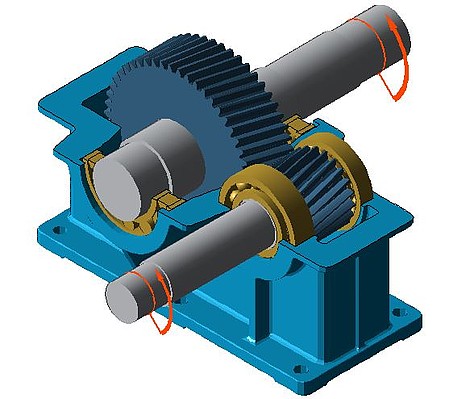

In roller bearings, there is line contact between the rolling elements and the raceway. If the rolling elements are perfectly cylindrical (cylindrical roller bearings) or tapered (tapered roller bearings), this leads to local pressure peaks when the end side of the rolling elements comes into contact with the raceway. This can result in local pitting damage in these areas. To avoid these pressure peaks, roller bearings are always designed with profiling along the longitudinal axis of the roller.

Read more here.