This unique software includes the latest results from the FVA research network - new calculation methods for fast, precise results.

Fast development processes thanks to powerful performance and intuitive operation

The new FVA-Workbench is significantly faster and easier to use. Individual gearbox components to complete systems can be developed in the shortest time possible. During the calculation process, built-in wizards automatically suggest suitable values which can then be adjusted manually.

Simple modeling of complex planetary stages

Even complex planetary stages can now be modeled at lightning speed thanks to add-in wizards. Users can model very complex planetary gear designs (e.g., Ravigneaux and Wolfrom sets), from consideration of installation conditions to automatic calculation of dependent variables (such as center distances and addendum modifications), in the shortest time possible.

Flexible and adaptable to special designs

Values automatically assigned by wizards can be adapted to individual requirements at any time, so that symmetrical systems as well as planetary gears, in which the planets are distributed asymmetrically, can be calculated. Variations, such as bore tolerances for planet pins or stiffness-dependent load distribution, can also be considered.

New features improve the accuracy and detail of results

Operationally stable gear design with load spectra

In the new version of the software, load spectra are considered in system-level calculations for the first time. Users can determine the service life of cylindrical and bevel gears as well as rolling bearings, enabling operationally stable gearbox designs.

New features:

- Specification of Woehler S/N curves or calculation according to ISO 6336 and ISO 10300

- Calculation of scuffing and wear damage according to AGMA 925-A03

- Flank fracture calculation according to ISO 6336-4

- Wear calculation according to Plewe (1980)

FEM feature enables importing and meshing in seconds

In addition to planet carriers and gearbox casings, wheel bodies can now also be imported in many common CAD formats. First, the wheel body is automatically adapted to the FEM mesh of the gear. The FEM meshing as well as positioning and connection to the gear model are then performed in just a few seconds. Automation, interactive user navigation, and user-friendly assistants make these steps extremely simple.

"Efficient FE methods are indispensable for optimizing the power density of gear stages. For this reason, WZL has been working on the successful development and validation of FE-based tooth contact analysis for more than 30 years. With the release of FVA-Workbench 5.5, free wheel body geometries can also be considered in the FE tooth contact analysis feature. The wheel body is imported as a CAD model and automatically connected to the FE model of the gear. Thanks to FVA GmbH‘s exceptional cooperation with the Universität Bayreuth CAD research institutes and the Laboratory for Machine Tools and Production Engineering (WZL) of RWTH Aachen University, software users can now easily and efficiently achieve weight saving potentials by adjustment of wheel body geometries."

Dr. Christoph Löpenhaus, Chief Engineer Gear Technology, Laboratory of Machine Tools (WZL) of RWTH Aachen

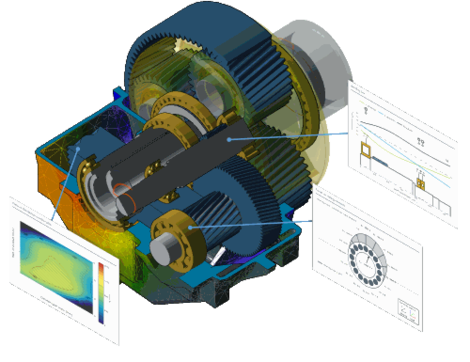

Realistic modeling of planet carriers, casings, and wheel bodies

Planet carriers, casings, and wheel bodies are realistically modeled using FEM. This also allows for problem-free interpretation of the calculation results. FE bodies are displayed in 3D, making it much easier to verify the validity of results.

New bevel gear calculations for fast, highly detailed analyses

The newly integrated BECAL 6 feature enables highly detailed analysis of bevel and hypoid gears. The results of FVA research projects 223 XII (local load capacity calculation) and 223 XV (contact pattern measurement) have also been integrated as calculation features.

New features:

- Local scuffing load capacity calculation according to Klein (FVA 519)

- Local micro-pitting resistance calculation according to Hombauer (FVA 516)

- Calculation and output of the dimensions of the numerically calculated contact pattern

- Quantitative comparison of the target and actual states of the shape and position of the contact pattern

“The new BECAL 6 makes bevel gear calculations in the FVA-Workbench even more powerful and user-friendly. The available features make it possible to perform calculations according to the latest cutting-edge research.”

Dr. Stefan Schumann, Technische Universität Dresden, Institute of Machine Elements and Machine Design

Easy output of results with drag-and-drop reports

With the reporting feature in the FVA-Workbench, customized reports can easily be created using drag & drop. Complex relationships are clearly visualized in structured sections, enabling effective evaluation of results.

Impress customers with even more report graphics

Version 5.5 includes more than 40 new display options for load spectra, force excitation of cylindrical gear stages, pressure distribution of worm stages, and more.

Particularly impressive, the graphics of the HTML reports can be rotated and zoomed, and value pairs can be read directly. This provides customers and users the same interactive experience, and gear design modifications can be discussed as early as the product development phase.